Combustible dust is a seemingly innocuous material that poses a serious and frequently disregarded hazard in various industrial sectors, from metalworking and pharmaceuticals to food processing and woodworking. A tiny ignition source, like a spark or a hot surface, can cause a violent and destructive explosion when fine particles of material, such as flour, wood, sugar, or metal, gather in a small area. The initial blast frequently dislodges more dust, leading to a secondary, more potent explosion that has the potential to destroy an entire facility.

How do fire system deficiencies impact business continuity? The dire consequences highlight a crucial question. A single fire system failure, from a non-functional detector to a faulty suppression unit, can lead to a catastrophic event that not only destroys physical infrastructure but also halts production, causes severe financial losses, and can result in long-term reputational damage. Therefore, proactive combustible dust hazard mitigation is not only a safety concern but also a key component of operational resilience and company survival.

The Fire Alarm Panel: Central Command

To manage this risk, a strong and well-maintained fire safety infrastructure is necessary. The fire alarm panel is the central component of this system. This central hub controls the entire fire safety system.

Heat sensors, smoke detectors, and specialized dust-specific detectors are just a few of the detection devices that send signals to the fire alarm system panel throughout a facility. When the panel receives a signal, it processes the data, can automatically activate suppression systems, and sounds alarms to notify staff. To avoid false alarms and guarantee a prompt, suitable response to a real emergency, a dependable panel is designed to discriminate between a minor incident and a serious threat.

Any facility handling flammable dust must maintain it properly and conduct routine testing because its operation is essential for both early warning and the automated start of suppression measures.

Beyond the Panel: A Layered Mitigation Strategy

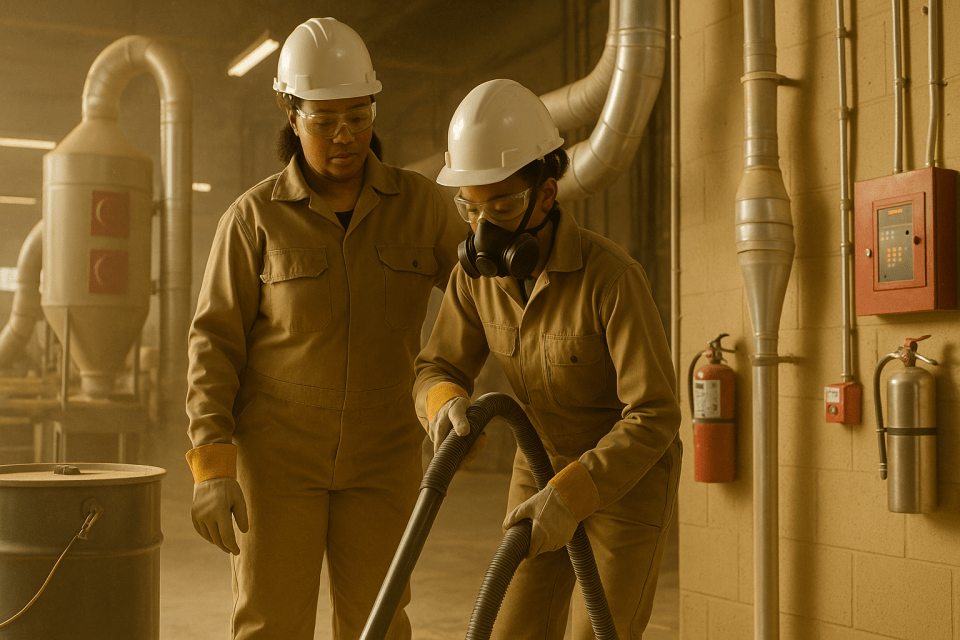

A thorough approach to combustible dust mitigation includes several essential elements in addition to the main alarm system. The first is strict housekeeping to avoid dust buildup. A basic and continuous task is regular cleaning with specialized vacuums, never using compressed air, which can cause dust clouds.

Second, it’s critical to control the sources of ignition. This entails putting in place stringent guidelines for hot work, making sure all electrical equipment is rated and maintained appropriately, and grounding all machinery to stop the accumulation of static electricity.

To isolate and contain possible explosions, engineering controls such as dust collection systems and explosion vents are also essential. While explosion vents on machinery or building walls can safely release the pressure from a deflagration, reducing structural damage, dust collectors collect particles at the source.

In Summary: Protect People and Continuity

In summary, the danger of flammable dust explosions is a significant and intricate issue that calls for a multifaceted strategy. Facility managers can give investments in strong technology and stringent procedures top priority by tackling the basic issue of how fire system flaws can jeopardize a company. Every precaution taken, from a dependable fire alarm panel to ongoing housekeeping and cutting-edge engineering controls, is an attempt to protect employees, guarantee business continuity, and secure the company’s future.

comments +